Parapor

Parametric Porcelain

.

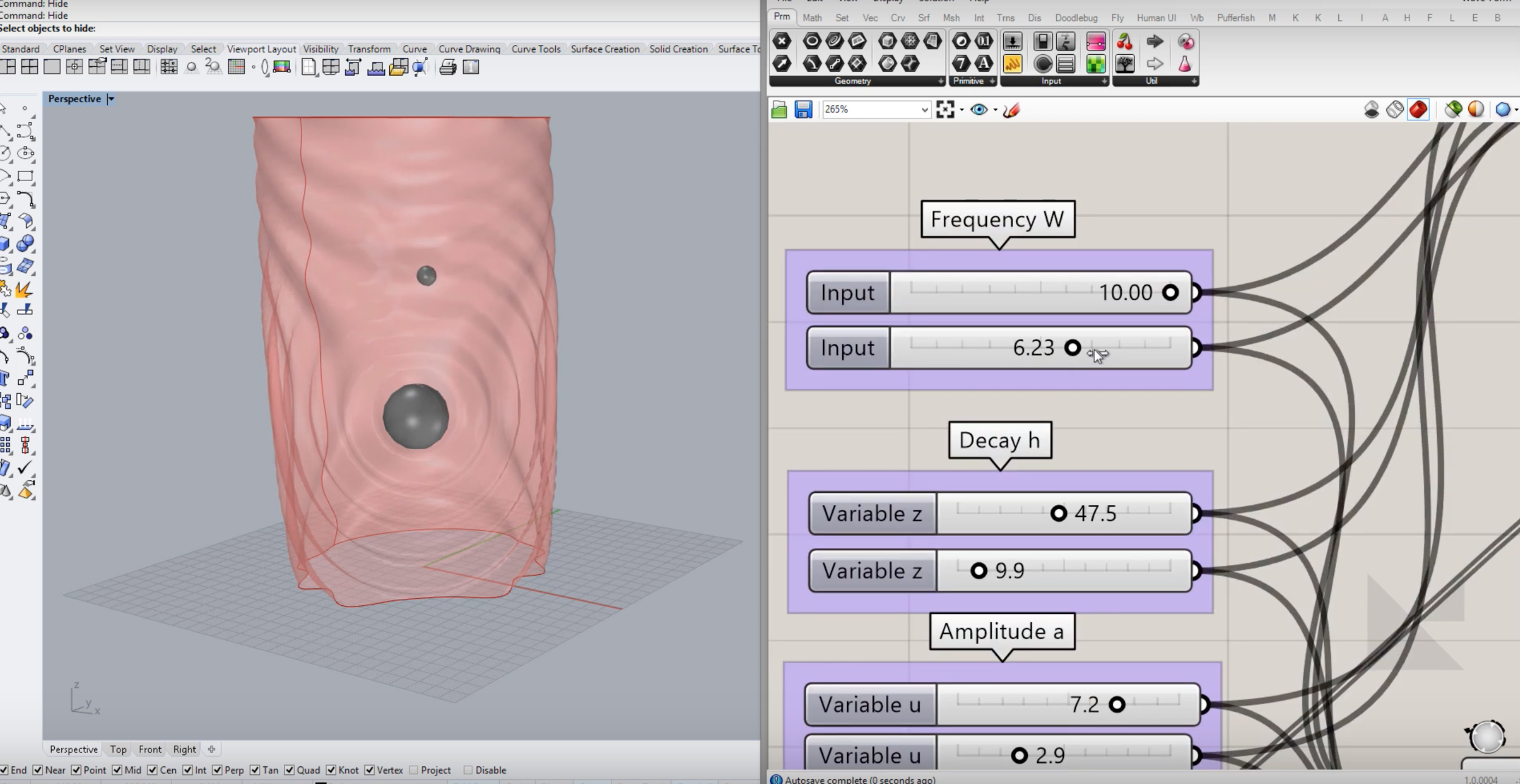

Parametric modeling is used to define a dimension’s ability to change the shape of a model’s geometry instantaneously when the dimension value is modified. It allows for the harmonized metamorphosis of a form.

Finding nature’s forms emerge in such a premeditated form of design reveals the careful orchestration happening all around us.

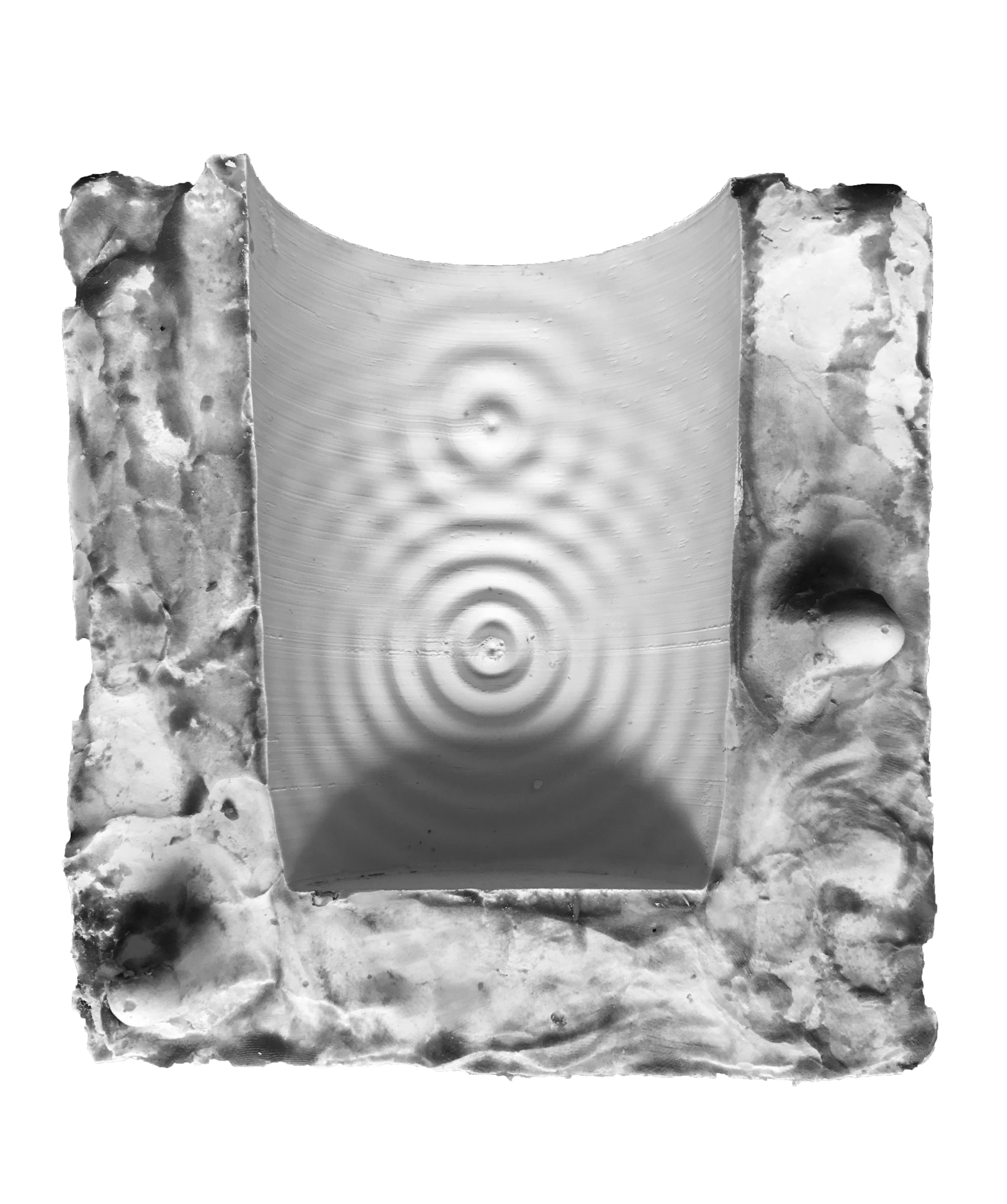

In the case of PARAPOR, the algorithm that acts on the surface of the model produces concentric ripples shaped by the variables of frequency, amplitude, and decay. The piece is then 3D printed for mold making.

Ceramic mold making opens up endless potential for creative expression. Not only does ceramic mold making enable you to repeat a form over and over again, it also makes individual forms lose their preciousness

The molds are filled entirely with ceramic slip, a processed liquid mixture of clay particles in water. The water in the slip is absorbed by the plaster, causing the clay particles to condense into solid clay, but only around the walls of the mold.

The longer the mold sits, the more water is absorbed, and the thicker the walls of the cup will be. When the desired thickness is reached, the remaining slip is poured out and the mold is removed. The ceramic positive can then be further worked, or left to dry and then kiln-fired.